The whole nine yards

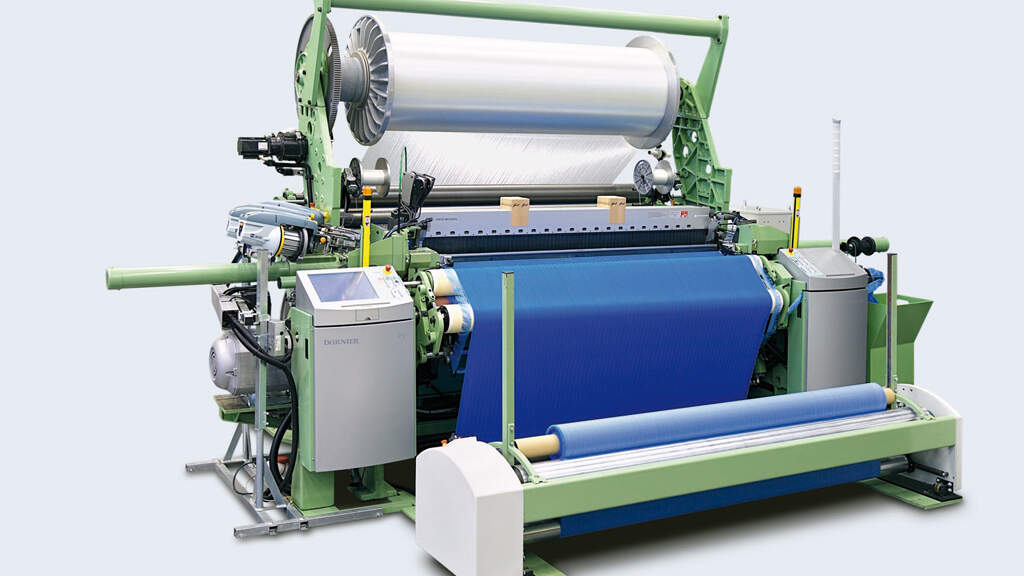

Thirty destination countries, formidable products such as 12 ton weaving machines and their spare parts, and a single point of contact to coordinate it all: this is the supply chain story of Lindauer DORNIER GmbH and DACHSER.

This weaving machine was in a class of its own. “It weighed over twelve tons,” recalls Daniele Borrescio, sales manager at DACHSER Air & Sea Logistics in Kaufbeuren. DACHSER shipped this heavy piece of machinery by air from Germany’s Lake Constance region to Osaka, Japan, for its customer Lindauer DORNIER GmbH. “A specialized transport such as this requires advance planning,” says Borrescio. “While this is a luxury we can afford, what is truly pressing is the worldwide delivery of spare parts with a lead time of often only a few hours.” Quick, flexible, cost optimized: according to Borrescio, that’s the spirit of the collaboration initiated on March 1, 2009 with the officially certified known consignor, Lindauer DORNIER.

In some respects, DORNIER is on “home turf” when it comes to air freight, as its name is synonymous with air freight development. Claude Dornier (1884-1969) was an aircraft engineer who began his aviation career as an employee of the legendary Count Zeppelin, and later wrote aviation history himself. After the Second World War and Germany’s disarmament, his son Peter Dornier founded the company Lindauer DORNIER GmbH in 1950 in Lindau on the shores of Lake Constance. Instead of aircraft, weaving machines now comprised the production list. Although the employees had no experience at the outset, they immediately set to work and made the company a success. It quickly achieved international standing with pioneering innovations in the textile industry, just as it had with aircraft construction in the past. For eight years now, Lindauer DORNIER has partnered with Dachser to transport its products across the globe via air freight.

From small parts to mega machines

DACHSER is now responsible for the company’s entire spare parts logistics in the air freight sector, ensuring that the weaving and special machines with spare parts are in good shape. DACHSER Air & Sea Logistics uses air freight to ship parts to over 30 destinations worldwide. It also handles customs clearance in the respective distribution countries.

Every day, the DACHSER branch in Kaufbeuren uses its own fleet of vehicles and drivers to pick up goods from DORNIER’s factories in Lindau and nearby Esseratsweiler. “We have provided the customer with a single point of contact for coordinating all of DORNIER’s enquiries and consignments,” explains Borrescio. “Even though the Kaufbeuren location has no direct connections to an international air cargo terminal, we cover the whole nine yards in air freight for Lindauer DORNIER GmbH. From flight data to proof of delivery, we fulfill every customer wish.”

The results speak for themselves: Every year, Kaufbeuren ships about 1,600 consignments, weighing around 220 tons. These shipments range from small parts to mega machines.